Selecting and Using Pushbuttons Switches and Indicators

The human-machine interface (HMI) is crucial to the safe and efficient operation of equipment and systems in industrial environments. Control panels, therefore, must be designed to comply with health and safety standards and be user-friendly. Designers need to emphasize intuitive, ergonomic design with logically arranged, visible, legible, and accessible controls and signals to enhance operator productivity and reduce stress.

To address these needs, designers must start by selecting appropriate components, such as pushbutton switches, selector and key switches, emergency stop buttons, multiple-headed pushbuttons, and pilot lights. These components must conform to government standards and be rated for industrial environments.

This article briefly discusses industrial control panel requirements. It then introduces example components from Schneider Electric to demonstrate the selection and application of industrial panel controls and signals to meet regulatory, efficiency, and ergonomic requirements.

Industrial control panels

Industrial control panels are HMIs that manage and monitor machine operations, providing crucial control and status information. Control panel design has become increasingly complex. Fast-developing automation technology and increasingly strict standards and regulations require proper design, installation, and testing. A crucial part of the design is selecting and placing components such as indicator lights, pushbuttons, and selector switches that affect operator accuracy, productivity, safety, and comfort.

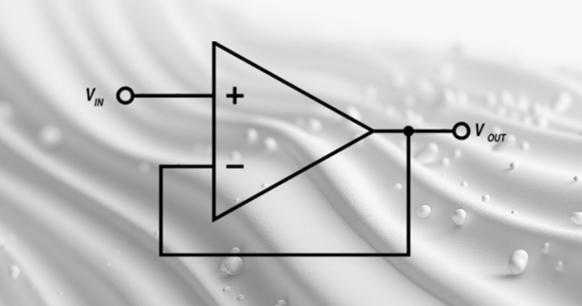

The two types of components on a control panel are controls and signals (Figure 1).

Controls include pushbuttons, selector switches, joysticks, and key switches. Signal components include pilot lights, annunciators, and specific readout devices like meters. Some components, like illuminated pushbuttons, combine both functions.

Component inventory control and assembly

The Harmony XB4 family of panel indicators and controls from Schneider Electric exemplifies robust, easy-to-install panel controls and indicators with flexible inventory management. The components are available as complete units, subassemblies, or basic elements (Figure 2).

For instance, the XB4BA31 is a fully assembled green pushbutton single pole-single throw (SPST) normally open (NO) switch with screw terminal connections. It comes ready for installation.

A slightly more flexible parts strategy is to stock the contact block and the pushbutton head separately. This allows a standard SPST-NO switch contact block like the ZB4BZ101 to have multiple pushbutton options, like the green ZB4BA3 (or various other colors or markings) that can be matched during assembly.

The most flexible strategy uses basic elements, including the ZBE101 SPST-NO switched contact block, the ZB4BZ009 mounting collar, and the desired color pushbutton head. This provides flexibility by allowing the switch configuration and pushbutton color to be changed during assembly.

Examples of Harmony XB4 units

In addition to the pushbutton switch, the Harmony XB4 line has a broad range of other control panel products (Figure 3).

The most common signaling device is the pilot light. The ZB4BV06 pilot light is a round, non-illuminated pilot light head for a 22 millimeter (mm) panel cutout. It requires a light source or light block. The ZBVB14 is a light block with a white LED that operates from a 24 volt AC-DC source. This is one of a group of behind-the-panel blocks that support head units in front of the panel.

The ZB4BD2 is a selector switch operating head for a 22 mm round panel cutout. It requires a separate switch contact block, as seen in the pushbutton switch assembly. An alternative is the ZB4BG2 key body selector switch head with two positions. It is intended to provide key-secured operation. This switch head also requires a separate contact block. Another switch head variant is the double-headed pushbutton switch, such as the Harmony ZB4BA7120 rectangular switch head with white and black unmarked buttons. It also fits into a 22 mm opening and requires a switch contact block.

The ZD4PA22 is a joystick controller head that moves in two directions with a spring return to the neutral position for more flexible control. The joystick also requires a separate body/contact assembly. Similar joystick controllers are available with four directions of movement, with or without the spring return.

This is a small sampling of the broad line of Schneider Electric control panel units. Contact and light block assemblies are also available with screw terminal, faston, or plug-in terminations. All units are robust, with high ingress protection ratings (IP66 to IP69) and an impact rating of IK06. They have an operating temperature range of -40°C to +70°C and a rated life of 10 million operations. They also meet international standards, including IEC, UL, CCC, EAC, and JIS.

Color selection

A selection of colors is available for the pilot lights and pushbuttons that can be added by using colored LEDs or translucent colored lens caps over a white LED. The white LED devices have the advantage that only a single device body needs to be stocked along with lower-cost colored lens caps, as opposed to multiple colored LED device bodies. The lens caps can also be marked with various icons, text, or symbols.

The choice of colors is governed by IEC Standard 60073, “Basic and Safety Principles for Man-Machine Interface, Marking and Identification - Coding Principles for Indicators and Actuators- 2002” (Figure 4).

The meanings of the color choices vary with the context. Red indicates a problem, yellow indicates a warning, and green indicates safe or regular operation. Blue is reserved for indicating a condition requiring action on the operator’s part, such as a prompt to input information.

White, grey, and black have no specific meanings and are used for indications such as start, stop, or reset.

Color may be combined with markings to ensure the correct interpretation of the control action.

Control panel ergonomics

The ergonomics in the interaction between humans and machines are meant to reduce human error, increase productivity, and enhance health, safety, and comfort. These goals can be met in control panel design by focusing on visibility, access, and organizational layout.

Control visibility has one fundamental principle: place the most essential information in the operator's field of view (Figure 5). The layout must consider the operator’s natural lines of sight.