Measuring Analog Signals in Low-Power Sleep Modes With the AVR® EA Family of Microcontrollers

In the vast landscape of embedded systems, understanding analog signals and harnessing their potential is crucial for designing efficient and power-conscious applications. Analog signals, in essence, are continuous signals that represent real-world phenomena. They are present in various electronic devices, from simple sensors to sophisticated communication systems. This blog post delves into the realm of analog signals, their prevalence and the fascinating integration of low-power modes in PIC® and AVR® microcontrollers, particularly in the context of analog signal processing.

Analog signals can be found in diverse applications, ranging from temperature sensors and accelerometers to audio systems and communication devices. These signals are the bridge between the digital world of microcontrollers and the analog environment they interact with. By accurately measuring and interpreting analog signals, microcontrollers can provide real-time data for decision-making and control processes.

PIC and AVR microcontrollers offer low-power modes that optimize energy consumption without compromising functionality. These low-power modes allow the microcontroller to conserve energy during periods of inactivity. This becomes especially crucial in battery-powered applications, where extending battery life is a paramount concern.

Measuring analog signals in low-power modes is an intricate dance between precision and power efficiency. Enabling Analog-to-Digital Converter (ADC) modules in microcontrollers during these low-power modes allows for continuous monitoring of analog signals with minimal power consumption. This capability becomes particularly advantageous in scenarios where intermittent, low-frequency data sampling is sufficient, as it enables the microcontroller to remain in a low-power state for extended periods of time. Measuring analog signals in low-power modes offers numerous advantages. Primarily, it ensures power efficiency, which is indispensable in battery-operated devices. By strategically employing low-power modes, developers can strike a delicate balance between responsiveness and power conservation, tailoring their applications to meet specific power requirements.

Application Overview

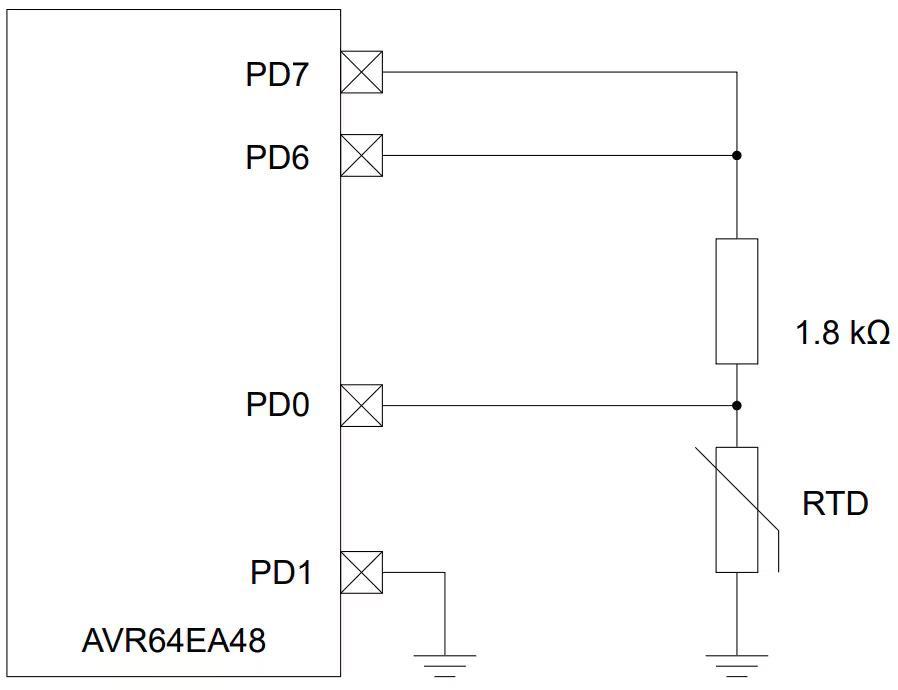

This example, centered around the AVR64EA48 microcontroller and developed using MPLAB® Code Configurator (MCC), demonstrates how to leverage analog voltage sensing while optimizing power consumption through low-power modes. This example uses a resistance temperature detector (RTD) sensor in conjunction with a 1.8 kΩ resistor to measure ambient temperature. The resistance of the RTD sensor varies in a known function of temperature; as temperature increases, the resistance of the RTD increases. This allows the microcontroller to periodically measure the voltage across the RTD and calculate the ambient temperature.

|

Figure 1: Application setup

To minimize power consumption, the AVR EA is configured to stay in Power-Down Sleep mode whenever an analog measurement is not in progress. In this Sleep mode, the AVR EA power consumption was measured at approximately 0.9 µA (with VDD = 3.3V). The Periodic Interrupt Timer (PIT), a part of the Real Time Counter (RTC), is set up to periodically generate interrupts to bring the device out of Sleep mode. When an interrupt occurs, the Digital-to-Analog Converter (DAC) is enabled to produce an output voltage of 1.8V to the 1.8k resistor to prevent self-heating on the RTD, and the ADC is enabled to start a differential conversion immediately.

|

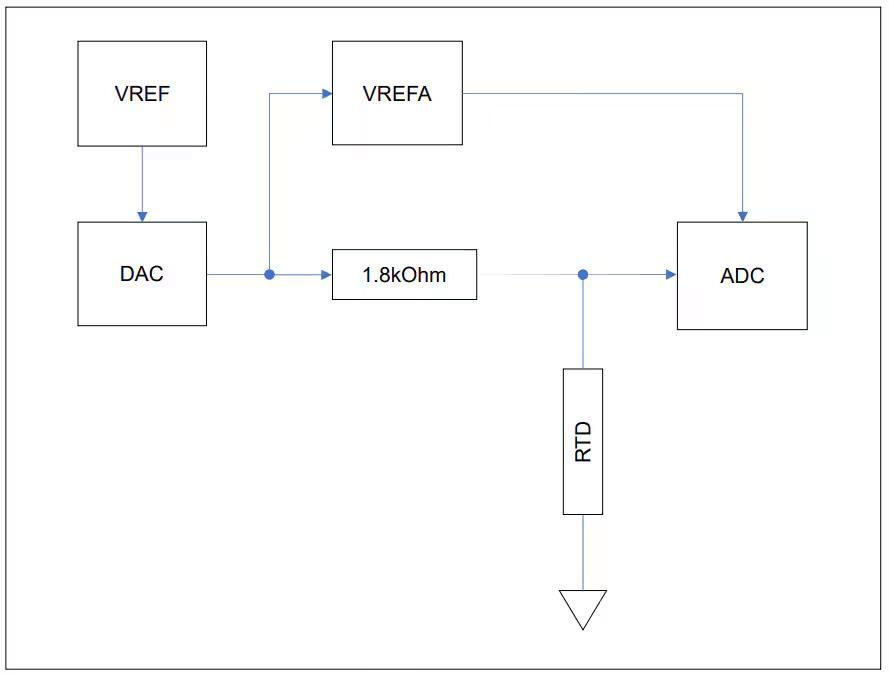

Figure 2: High-level hardware block diagram showing microcontroller peripherals and components

As soon as the ADC conversion is complete and the result is saved, the DAC and ADC are disabled; then the CPU performs the calculations necessary for converting the previous ADC value into resistance and temperature and puts the device back to sleep. When the DAC and ADC are both enabled after the device comes out of Sleep, the DAC output stabilizes before the ADC is ready to start its first conversion, eliminating the need for additional delays in software.

Application Results

Various strategies were tested to minimize power consumption (higher/lower CPU+ADC clock speeds, PGA on/off with less/more conversions), but in this case the overriding issue is the fact that the DAC must supply nearly 1 mA of current to the RTD sensor while ADC conversions are in progress. Therefore, the best strategy is to run both the CPU and ADC as fast as possible (10 MHz and 5 MHz clocks, respectively) with maximum PGA gain so the conversion time and the time that the DAC must supply 1 mA is minimized. With this configuration, a burst of 16 ADC conversions takes only 119 µs. During that 119 µs of conversion time with DAC enabled, microcontroller supply current was measured as 8.0 mA (this includes what is needed by the DAC to drive the RTD, with VDD = 3.3V). Note that if there is one conversion per second, the average current will be: 119 µs / 1s × 8 mA = 1.19e-4 × 8 mA = 0.95 µA.

Measured average current consumption is 0.9 µA + (0.95 µA × n), where n is the number of RTD temperature measurements per second:

|

n |

Current Consumption (with VDD = 3.3V) |

|

2 |

2.8 µA |

|

4 |

4.7 µA |

|

8 |

8.5 µA |

|

16 |

16.0 µA |

|

32 |

31.0 µA |

|

64 |

62.0 µA |

Table 1: Average current consumption per number (n) of RTD measurements per second

In conclusion, the symbiotic relationship between analog signals and low-power modes in PIC and AVR microcontrollers showcases the continuous evolution of embedded systems. As technology advances, the demand for energy-efficient solutions becomes more pronounced. Harnessing the power of analog signals in low-power modes not only enhances the performance of microcontroller-based applications but also paves the way for sustainable and resilient electronic designs. Developers navigating this intersection will find themselves at the forefront of innovation, creating devices that are not only smarter but also more energy-conscious.